This capacitor series was designed for AC and pulsing applications. The units are rated for 135 VRMS and 67 VRMS (to 400 Hz), but may also be used for all DC applications up to 200 VDC and 400 VDC respectively.

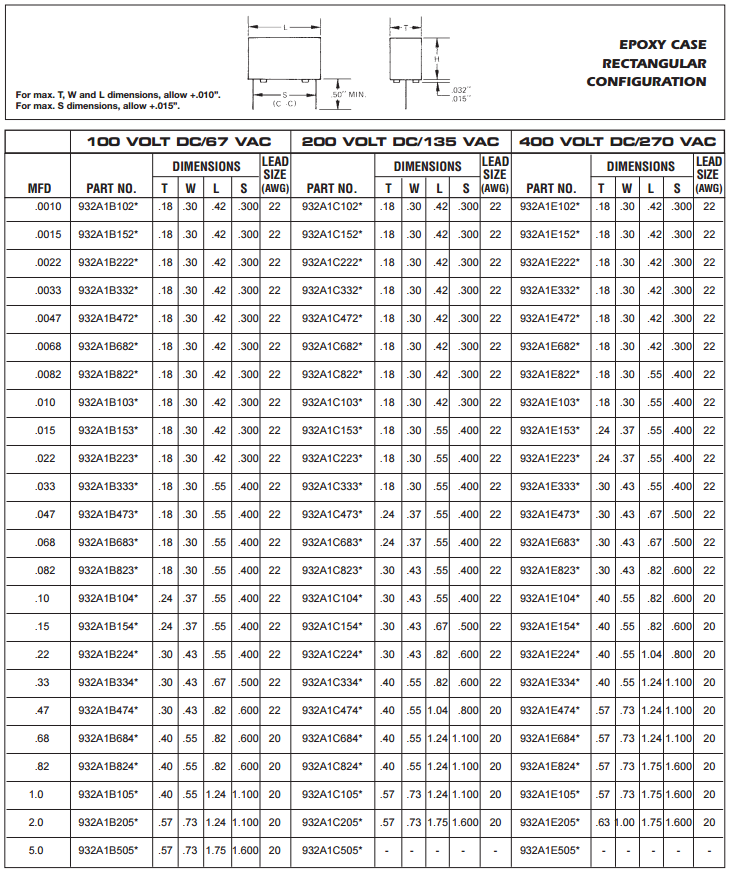

A wide range of sizes and styles is available. You can choose from axial-lead wrap and fill in oval and round configurations or rectangular epoxy case with axial and radial leads.

Two types of dielectric material are used: metallized polypropylene and polypropylene and foil. Metallized versions are offered in all styles.

Polypropylene and foil capacitors may also be specified in all standard styles.

All capacitors feature extended foil construction and standard tin-coated copper-clad steel leads. Nickel, copper, dumet and other special leads are available.

Protective clear wrap is offered on all wrap and fill units.

The potting material and endfills of Electrocube’s capacitors meet or exceed the flammability requirements of UL94VO.

Dimensional variations for all MFD values are available with the same volume to meet your design requirements.

| Temperature: | -55°C to +85°C at rated voltage; to +105°C with 50% voltage derating. |

| Dielectric Voltage Test: | Will withstand the application of 150 VDC, 300 VDC and 600 VDC on 67 VAC, 135 VAC and 270 VAC respectively at 25°C for a period not to exceed 1 minute; current limited to 5 mA. |

| DC Life Test*: | Will withstand the application of 138 VDC, 280 VDC and 560 VDC, respectively, on the 67 VRMS, 135 VRMS and 270 VRMS parts at 105°C for 250 hrs., with not more than 1 failure in in 12 permitted, current limited to 5 mA. |

| Dissipation Factor: | Shall not exceed 0.1% at 25°C for values to 1 mfd; 0.2% for values over 1 mfd. |

| Dielectric Absorption: | Shall not exceed 0.1% at 25°C per MIL-C-19978 |

| Acceptance Criteria: | Measurement frequency for capacitance and dissipation factor shall be 1000 Hz for values up to 1 mfd and 120 Hz for values of 1.0 mfd and up. |

| Insulation Resistance: | At DC voltages of 100 VDC (67 VAC), 200 VDC (135 VAC), 400 VDC (270 VAC), 1000 VDC (660 VAC), units shall meet the minimum values below: |

NOTES:

For information regarding insulating sleeves, mountings, special terminals, non-standard leads, circuit connections and other hardware, please consult factory.

For styles and ratings not shown, or for unusual requirements necessitated by special circuit applications (including higher IR or lower DF), consult the factory direct.

All Electrocube film capacitors have endfills and tape that meet or exceed the flammability requirements of UL94V0.